Ceramic Insulated Band Heaters can meet the demand for energy conservation & operation efficiency.

They are capable of generating higher temperatures essential to process today’s resins.A helically wound resistance coil made from nickel-chrome wire is precisely strung through specially designed ceramic insulating bricks, forming a flexible heating mat.

These heaters transmit heat through both conduction & radiation. The element winding is designed to heat the ceramic blocks to the point at which they radiate energy into the barrel as well as conduct energy by being in contact with the barrel - fit is not as critical as in other types of bands.

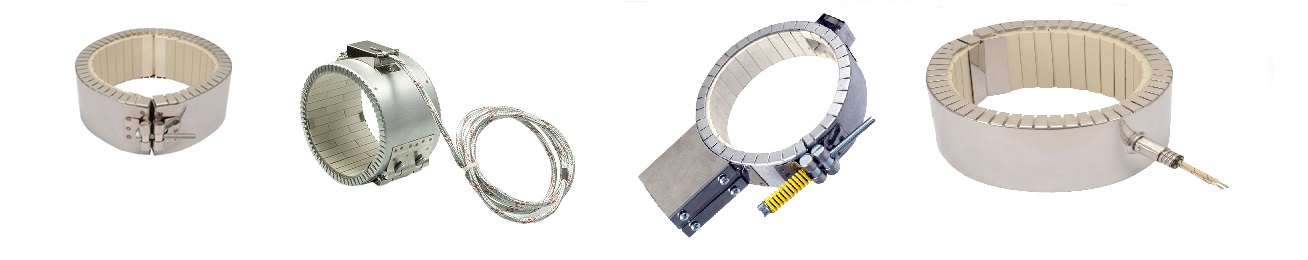

Termination Options

- HORIZONTAL POST TERMINALS

- VERTICAL POST TERMINALS

- CERAMIC BLOCK TYPE TERMINATION

- HIGH TEMPERATURE QUICK DISCONNECT PLUG

Clamping Options

- SPRING LOADED SCREW CLAMP

- STANDARD ALLEN BOLT CLAMP

-

FLANGE TYPE CLAMP

Technical Specification

| Resistance |

+10% -5% |

| Wattage |

+5% -10% |

| Max. Watt Density |

8 watts / sq.cm |

| Voltage |

220V AC to 480V AC |

| Minimum Dia. | 38 mm |

| Minimum Width | 25 mm |

| Overall Thickness | 15 mm |

| Maximum Temp |

800 oC |

INSTALLATION & MAINTENANCE

- The surface of the barrel and ceramic band heater must be clean and free from all contaminants that might liquefy under heat and find there way into the heater elements, carbonizing and becoming conductive.

- Ceramic heater works on conduction and radiation principle and they do not require the same clamping force essential on all other types of band heaters

- To prevent the overheating and heater failure, adequate temperature controllers should be installed.

- Eliminate contamination of oil, plastic, dirt etc on cylinder surface

- Keep all electrical connections properly protected to avoid accident

Features

- Excellent dielectric strength at high temperatures with high voltages

- Ability to interlock and provide a more rigid structure

- The flexible design allows easy install and removal

- Reduces the chances of damaging internal coils in transit and handling

Applications

We specialize in a variety of services. Our aim is to deliver the top level of customer

service based on your requests.

- Injection Molding Machine

- Compounding

- Blow moulding

- Plastic Processing Machinery.

We hope that with our services you will receive the most personalized help in purchasing any

kind of products you are looking for.

Ordering Information

- Operating voltage

- Wattage (W)

- Inside diameter (Ø)

- Length of the heater (L)

- Termination & Clamping Style

- Length

- Quantity

We specialize in a variety of services. Our aim is to deliver the top level of customer

service based on your requests.