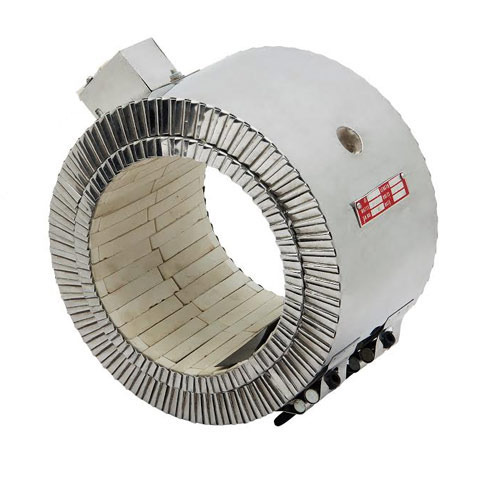

Energy Saving Band Heaters are ideally manufactured to. reduce the time taken to heat the barrel and reduce the energy cost, with optimized heating. In addition to the in built 4mm thick heat saving insulation, an extra 12mm – 25mm thick flexible insulation is added on the external sheath covered with an additional metal layer. The power saving on these heaters ranges between 25 – 40% depending on the insulation thickness selection.

Energy Saving Ceramic Band Heaters are Specifically designed and engineered to meet the ever increasing demand for energy conservation and to improve operation efficiency capable of generating higher temperature essential to process today's high temperature resins.

| Sheath Material | Aluminised Steel/ SS |

| Sheath Temperature | 500 °C Max. |

| Insulation Material | High temp steatite insulators |

| Heating Element | NiCr 80:20/ NiCr 60:16 |

| Voltage Rating | 48 V to 440 V (Single/Dual/ Three Phase) |

| Power Rating | 35-45 W/in2 |

| Power Tolerance | +-10% |

| Resistance | +-5 percen |

| Energy Saving Insulation Material | Ceramic Fibre |

| Energy Saving Ratio | 25% to 40%depending on the insulation thickness |

| Wall Thickness | 25mm to 40mm |

| Minimum Inner Dia | 60mm |

| Minimum Width | 35mm |

| Clamping | M6 x 45mm allen key or 3/16" screw fastener |

| Lead Connections | Screw Post/ Lead wires |

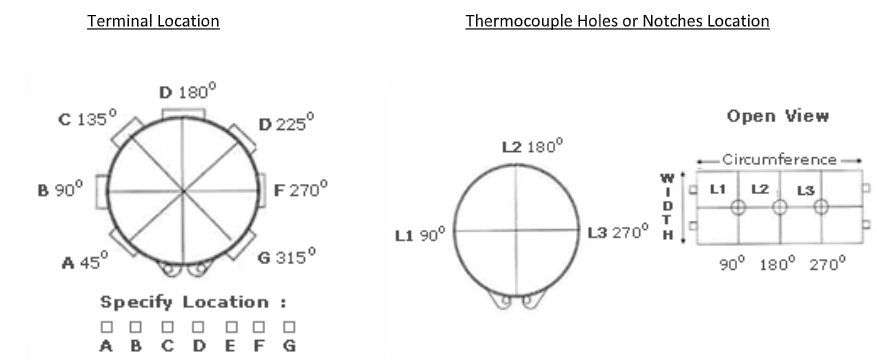

| Termination Connection Options |

|

| Thermocouple Hole | Standard dia 19mm,bigger or smaller dia on request |

We specialize in a variety of services. Our aim is to deliver the top level of customer service based on your requests.

We hope that with our services you will receive the most personalized help in purchasing any kind of products you are looking for.

We specialize in a variety of services. Our aim is to deliver the top level of customer service based on your requests.